When it comes to building or renovating spaces exposed to high humidity, such as bathrooms, kitchens, basements, and semi-outdoor areas, selecting the right material is crucial for long-lasting durability and protection. Moisture-prone areas require building materials that won’t swell, crack, or become a breeding ground for mold and mildew over time. This is where water-repellent fibre cement boards shine as an ideal solution. Among the industry’s top choices is Ecopro Plus by Sahyadri Industries Limited, a premium fibre cement board with Type A Class 3 certification per BIS 14862 and ISO 8336 (E) standards, known for its impressive moisture resistance properties and high strength.

Here’s a closer look at why water-repellent fibre cement boards like Ecopro Plus are revolutionizing construction in moisture-prone areas and how they deliver unmatched performance for these challenging environments.

- Superior Moisture Resistance

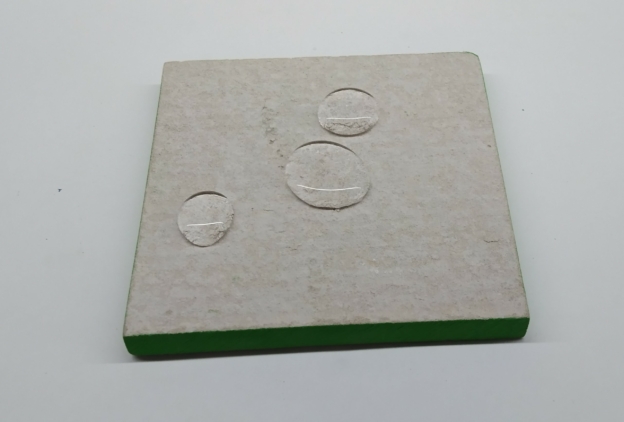

Moisture damage is a common issue in high-humidity environments, leading to weakened structures, swollen materials, and unsightly wall damage. Conventional building materials like wood, gypsum, and drywall are prone to absorb moisture, which can cause them to warp, crack, or even harbor mold over time. Ecopro Plus is engineered to resist moisture absorption. This low water absorption rate ensures that the material remains unaffected by humidity and constant moisture contact, preventing swelling, cracking, or degradation over time.

PHOTOS

- Unmatched Strength for Long-Lasting Durability

Fibre cement boards are crafted to handle the stresses of moisture and other environmental factors without compromising on structural integrity. Fibre cement board have a high impact strength, around 9–12 kJ/m², depending on thickness, Compare to wood (8–10 kJ/m²) and gypsum (1 kJ/m² or less).

The properties ensures that walls made from fibre cement board remain stable, firm, and intact for years, even in areas that are constantly exposed to water.

- Ideal for Exterior application

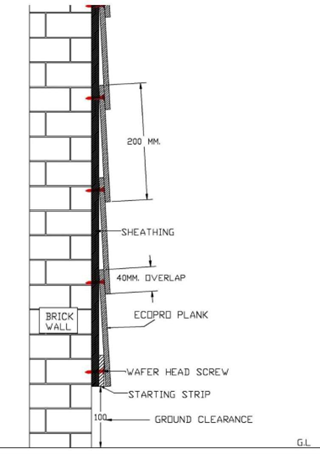

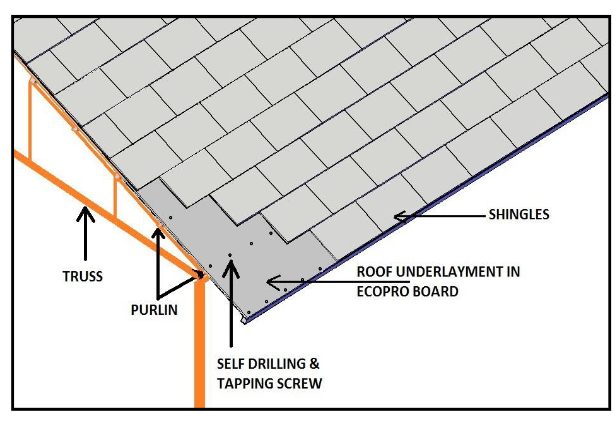

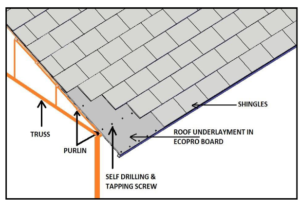

Water-repellent fibre cement boards are ideal for exterior applications like façades and roof underlays, where strength and resilience are essential.

- Why It Matters for Façades: The façade is often the most exposed part of a building, facing rain, humidity, and heat. Water-repellent fibre cement boards ensure that the façade remains intact, minimizing damage and the need for repairs, even in high-humidity environments.

- Why It Matters for Roof Underlays: Roof underlays need to protect the structure from moisture infiltration, especially during heavy rains. Water-resistant fibre cement boards act as a reliable secondary barrier, preventing leaks and extending the roof’s life.

- Aesthetic Flexibility: Diverse Textures and Finishes

Water-repellent fibre cement boards don’t compromise on aesthetics. Its available in a range of textures and finishes—including wooden texture, stone, waves, aquatic and brick—these boards provide the look of traditional materials without sacrificing performance. This versatility allows architects to achieve a variety of visual effects without losing technical benefits.

- Environmentally Sustainable: A Long-Life, Eco-Friendly Choice

Fibre cement boards contribute to environmental sustainability through their long life cycle and lower replacement frequency compared to other materials. They’re manufactured with energy-efficient processes and, due to their durability, produce less waste over time. By resisting damage and degradation, they require fewer resources for repair or replacement.

Conclusion

Water-repellent fibre cement boards have set a new benchmark for performance in moisture-prone areas, combining superior moisture resistance, high impact strength, fire resistance, and low maintenance into one versatile material. For façades and roof underlays, these boards deliver long-term protection, durability, and aesthetic appeal, making them an invaluable asset for any project facing the challenges of humid or wet climates. By choosing fibre cement, builders and architects gain a high-performance material that stands up to the elements while preserving structural integrity and design appeal for years to come.